Ever wondered how to prepare concrete surfaces for sealing? Or why some concrete looks amazing while others don’t? It’s all about the prep work before sealing. Getting your concrete ready for sealing is essential. It makes your concrete look better and last longer.

Preparing your concrete for sealing means making sure the sealer sticks well. This creates a barrier against water and stains. You need to consider the concrete’s age, the weather, and the right tools. We’ll guide you on how to do it right, so your concrete looks its best.

Key Takeaways

- New concrete should be cured for at least one month before sealing.

- Dry conditions are essential; sealers won’t bond with damp concrete.

- Temperature during application should be above 50 degrees Fahrenheit.

- Acrylic sealers are cost-effective and have quicker dry times.

- Surface preparation errors are responsible for 40% of sealing-related issues.

- Regular maintenance can extend concrete lifespan by up to 50%.

Understanding the Importance of Concrete Sealing

Sealing concrete surfaces is vital for keeping them looking good and lasting long. It does more than just make them look nice; it also protects them. A good guide on sealing concrete can help you get the most out of it, whether it’s for driveways, patios, or indoor floors.

Benefits of Sealing Concrete

Sealing concrete adds a protective layer, making it last 5 to 10 years longer. It stops moisture from getting in, which can really damage it, even more so outside where moisture is a big problem. Without sealing, concrete can crack up to 30% of the time because of freezing and thawing.

Also, sealers can cut down on wear from people walking on it by about 70%. This is important for places like garages and walkways that get a lot of use.

Common Problems Avoided by Sealing

Sealing concrete can stop many issues, like stains from spills, by up to 80%. It also guards against environmental damage, saving you about 50% on repair costs over time. Knowing the best sealing methods and how often to do it is key to keeping your concrete in great shape.

Assessing Your Concrete Surface

Before you start preparing for concrete sealing, check your concrete surface well. Look for any damage or wear that could affect the sealing. A good check ensures the sealer sticks well, making your concrete last longer. Keep a checklist for the concrete surface pre-seal to help you stay on track.

Identifying Damage and Wear

Check the concrete for cracks, discoloration, or pitting. These can stop the sealer from sticking. Also, find areas that need repair or cleaning. The concrete surface profile (CSP) levels help decide how to prepare the surface. For example, thin-film coatings need CSP levels of 2 to 3, while thicker overlays might need a CSP level of 5 or more.

Checking for Moisture Issues

It’s important to check if the surface is damp. Dampness can stop the sealer from sticking. Use moisture meters or the plastic sheet test to see if there’s moisture. Managing moisture well is key to a successful sealing project. Make sure to remove all contaminants before applying the sealer. This will help the sealer stick better and last longer.

Tools and Materials Needed for Preparation

Getting a concrete surface ready for sealing takes the right tools and materials. The right tools make the prep work easier and ensure the best results. Following the best practices for concrete sealing prep helps the sealed area last longer and work better.

Essential Tools for Concrete Preparation

Having the right tools for concrete prep is key to a good seal. You’ll need a pressure washer, mop, bucket, and degreaser to clean the surface. Also, concrete crack filler, painter’s tape, and protective gear are important for quality work.

Each tool has a specific role. Together, they help prepare the surface for sealing.

Recommended Sealers and Their Types

Choosing the right sealer is important for the concrete’s look and performance. There are acrylic, water-based, solvent-based, and penetrating sealers for different needs. For example, Repore concrete sealer works well for both inside and outside surfaces.

It protects against water, chemicals, and UV rays. Knowing the differences in sealers helps get the best results for your project. Learn more about best practices for concrete sealing prep to improve your sealing work.

Cleaning the Concrete Surface

Getting a concrete surface ready involves a good clean. This first step is key for the best results when sealing. It means removing dirt and debris, making the surface ready for more steps.

Removing Debris and Dirt

Begin by getting rid of loose dirt and debris. Sweeping or using a vacuum works well. Then, wash the surface to remove grime and stains.

For tough surfaces, a high-pressure washer is best. It’s great for outdoor areas. Regular cleaning helps keep concrete looking good and lasting longer, avoiding mold, mildew, and salt damage.

Choosing the Right Cleaning Method

The right cleaning method depends on the stains and surface condition. For oil stains, a degreaser is helpful. pH-neutral products often don’t need rinsing, saving time.

Try mixing 1 cup of baking soda with 2 cups of white vinegar. Let it sit for 30 minutes before scrubbing and rinsing. Using the best cleaning methods prepares the surface for sealing.

Repairing Damaged Areas

Fixing damaged concrete surfaces is key to making sealants last longer. You need to fill cracks and holes and smooth out pitted areas. This makes sure the surface is ready for sealing.

Filling Cracks and Holes

Begin by filling cracks and holes. Choose a patching compound designed for this task. Ensure the area is clean and prepared for the patch.

Small cracks can be fixed quickly. But bigger holes might need more material. Always clean the area well to help the patch stick.

Resurfacing Pitted or Spalled Concrete

When damage is deep, you need to resurface the concrete. This means adding a new layer to make it even. It makes the surface look better and last longer.

Let the new layer cure as directed. This ensures it’s strong before you seal it. Good repair work helps the concrete resist stains and wear.

Drying and Curing Concrete

Drying and curing concrete are key steps before sealing. It’s important to make sure the concrete is dry before sealing. This ensures the sealer works well.

Moisture levels before sealing can affect how well the sealer sticks. This can lead to problems and shorten the sealer’s life. Knowing how to dry and cure concrete is important for lasting results.

Importance of Drying Before Sealing

It’s critical to check if the concrete is dry before sealing. Moisture in the concrete can cause the sealer to fail. This can lead to poor adhesion and less protection against wear.

Waiting for the concrete to dry properly is important. This helps the sealed surface last longer.

Optimal Curing Times and Conditions

The curing process usually takes at least 28 days. This lets the concrete reach its strongest state under the right conditions. These conditions include keeping humidity levels between 80% and 85%.

Using methods like water curing or covers is important during this time. They help keep the concrete hydrated and prevent it from drying too soon. Monitoring the environment is key to ensure the concrete cures well.

After curing, you can start applying a sealer. This is usually 24 hours after cleaning. It helps protect the concrete from moisture and chemicals.

Preparing for Seal Application

Knowing the right conditions for seal application is key for lasting results. Following concrete sealing tips can make your sealant work better. Paying attention to temperature and moisture is very important.

Determining the Right Temperature and Weather Conditions

Sealing works best when it’s over 50°F and the weather is dry. Sealing in high humidity or rain can fail. Aim for a 70°F temperature for the best results.

Keep an eye on the weather. Unexpected changes can ruin your project.

Testing for Moisture Levels

It’s vital to check moisture levels before sealing. The plastic sheet test can show if it’s dry. A dry surface is necessary for the sealant to stick well.

New concrete needs at least 30 days to cure before sealing. This prevents moisture problems during the sealing process.

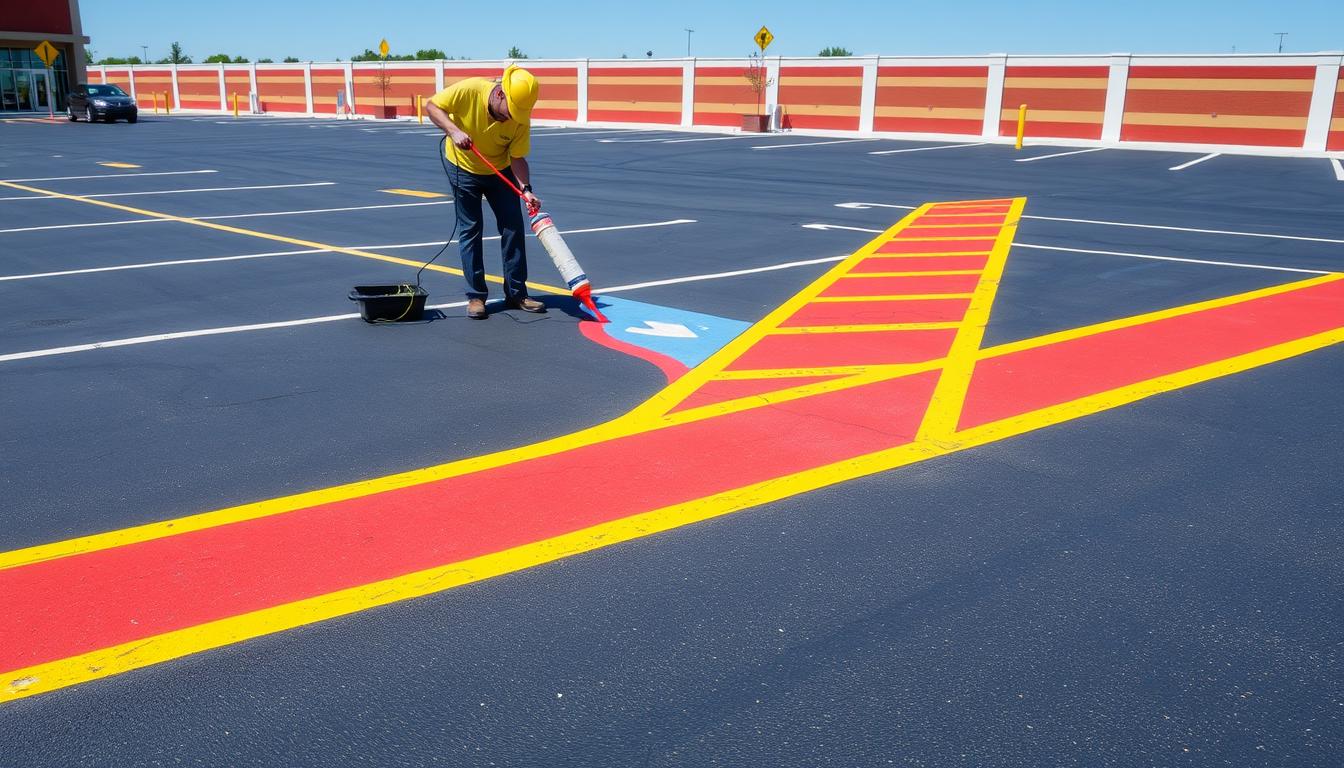

Applying the Sealant

After preparing the concrete, it’s time to apply the sealant. Choosing the right method is key for the best results. You can use sprayers for big areas or rollers and brushes for smaller ones. The method depends on the area size and the look you want.

Choosing the Right Application Method

Think about the size of your project when picking a method. Sprayers are fast for big areas, saving time. Rollers and brushes are better for small, detailed spots. Make sure the method fits the sealant type for the best results.

Best Practices for Even Coverage

Apply the sealant in thin, even layers for the best seal. This prevents pooling and ensures full coverage. Follow the maker’s advice on how to apply and how long to wait for it to dry. The right temperature and humidity help it cure faster.

Regular checks and touch-ups can make the sealant last longer. This keeps it working well to protect your concrete.

Maintaining Sealed Concrete Surfaces

Keeping sealed concrete surfaces in good shape is key to their long-term look and durability. By sticking to some simple care tips, you can make your concrete last longer. This not only keeps it looking great but also saves you from expensive fixes down the line.

Regular Maintenance Tips

Cleaning your sealed concrete regularly is a must. Use cleaners made for sealed surfaces to avoid harming the seal. Sweep often to get rid of dirt and prevent stains.

Also, clean up spills right away to keep your surface looking clean. Set up a cleaning schedule and check your seal often. This way, your concrete will stay in top condition for a long time.

Signs You Need to Reseal

Knowing when to reseal your concrete is important for its health. Watch for signs like discoloration, fading, or peeling of the seal. If you see dull spots, it’s time to reapply the seal.

Ignoring these signs can lead to bigger problems and more expensive fixes. So, act fast when you notice any issues to keep your concrete in great shape.

Safety Precautions During Sealing

When you seal concrete, safety comes first. Taking the right steps can keep you and the area safe. With the right gear and techniques, you can lower risks a lot.

Safety Gear to Use

Choosing the right safety gear is key. You’ll need gloves to avoid skin contact with harmful chemicals. Goggles protect your eyes from splashes, and respirators filter out bad fumes. Wearing long sleeves helps too.

Always take safety seriously to keep your work area safe.

Handling Sealants Safely

Safe handling of sealants is important. Always follow the manufacturer’s instructions. Make sure you apply sealants in areas with good air flow.

Keep sealants in a cool, dry spot, away from heat or sunlight. Learning about safety can help prevent accidents and make your job safer.

Why Choose HT Paving and Seal Coating Services?

Choosing the right paving contractor is key to a successful project. HT Paving and Seal Coating Services is a top choice. It’s known for quality and has a long family history. With over 30 years in the concrete business, it’s a trusted name in the Bay Area.

Family Business Heritage

HT Paving’s legacy is built on years of family experience. This means every project gets a personal touch and careful attention. Clients know their concrete is in good hands with a family business.

Commitment to Customer Satisfaction

HT Paving puts customer happiness first. It offers flexible payment plans and fair prices. This way, homeowners can keep their concrete looking great without breaking the bank. Regular sealing shows HT Paving’s dedication to making clients happy with the service and results.

Contact Information for HT Paving and Seal Coating Services

Looking for help with your paving needs? HT Paving and Seal Coating Services is ready to assist. Call (415) 774-6424 for inquiries or to book services. Our team has over 20 years of experience in Napa, CA, making sure your surfaces last and look great.

How to Reach Us

We’re committed to providing top-notch support and service. Need info or help with a project? Reach out to us. Our licensed team will help you with all your paving needs.

Service Areas in the Bay Area, California

HT Paving covers many areas in the Bay Area. We offer services for both homes and businesses. Our work includes fixing cracks and sealing concrete, boosting your property’s value and safety. Choose HT Paving for quality services that protect your concrete from the weather.